After the 1888 fire the remaining building was bought for the fire brick factory.

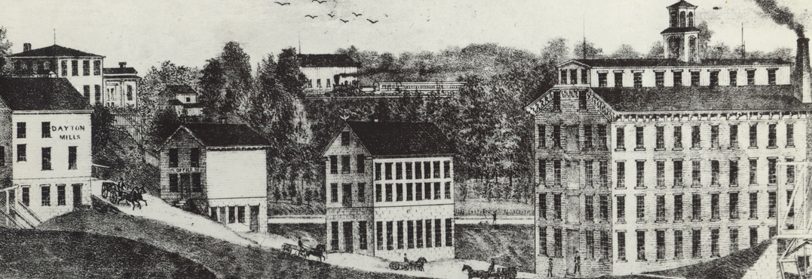

In August, 1892, the Ottawa Paving Brick Company, under the management of John W. Channel, who, for several years prior to this date, had been superintendent of Hess, Crotty & Williams brick factory, leased the brick works at Dayton, Ill. For three years this plant was run successfully, when, in November, 1895, the Standard Fire Brick Company, of Ottawa, Ill., was organized by Thomas D. Catlin, John W. Channel, M. W. Bach and E. W. Bach, with $25,000 capital stock. The company bought the Dayton property, consisting of the large, substantial, four-story stone building, formerly used as a woolen mill, and also the three-story frame building, used for many years as a horse collar factory, together with all the clay lands, water-power and machinery. John W. Channel was made president and general manager, Thomas D. Catlin, vice-president and treasurer, and E. W. Bach, secretary.

Shortly after the Standard Fire Brick Company had been legally organized and had commenced business, negotiations were entered into with the firm of Hess, Crotty & Williams for the purchase of their brick factory, located about a mile east of Ottawa, at a station called “Brickton.” The capital stock of the Standard Fire Brick Company was increased to $50,000, and the purchase of the plant of Hess, Crotty & Williams effected, and the company assumed control in May, 1896, with the same set of officers that the original Standard Fire Brick Company had, each private individual of the old firm of Hess, Crotty & Williams taking an interest in the company which purchased their plant.

The Dayton plant is situated four miles north of Ottawa, on the Fox river branch of the Chicago, Burlington & Quincy railroad system, and has its own sidetrack along the yards, and the Ottawa factory is located on the Chicago, Rock Island & Pacific main line, with a side track at the factory also. Thus the company has double the shipping facilities that any concern located on a single system would have, saving, of course, a great deal of annoyance and the expense caused by transferring from one road to the other. The company is a member of the Western Railway Weighing Association, from which a great benefit is derived.

At the Dayton factory the company has abundant water-power, and at Ottawa steam-power is used. Both places are heated thoroughly by a complete system of steam pipes, and they are also amply equipped with the usual dry pans, pug mills, clay crushers, conveyors, hand and power presses, clay bins and auger machines; no steam process being used in the manufacture of their wares.

The company has 65 acres of clay land, all underlaid with a vein of fire clay, most of it within 8 to 16 feet of the surface. At Ottawa, on top of this fire clay, there is a vein of coal about 22 inches in thickness, and above this coal a vein of common clay, varying from common yellow clay to one having the nature of soapstone. This yellow clay, properly mixed with a proportion of fire clay, is used in making their sidewalk tiles. At Dayton, on the west side of the river, there is, above the fire clay, besides a vein of coal, an extensive bed of valuable shale about 30 feet in depth. This makes good common ware, and mixed with a little fire clay, makes as fine a sidewalk tile as one will find anywhere in the country. On the east side of the river, where the main supply of the company’s fire clay is obtained, there is nothing above the fire clay except a bed of excellent gravel about five to eight feet in thickness. This gravel makes is possible to maintain the roads to the factory in excellent condition.

Fire brick and fire clay articles are the company’s main product. The market for this material is, besides Chicago, the great trade center of the West, all of the northern part of this State, Iowa, Wisconsin, Minnesota and Michigan, all of them great manufacturing states. Their competitors in the fire clay materials are very few, while the competitors in the common clay products are many, nearly every location of any size at all having its own common brick yard.

Many of our people do not realize the vast diversity of clay deposits in the close proximity to Ottawa, and their immense wealth that would result from their proper development, and in order to show the great variety of clay we have at Ottawa, as well as at Dayton and Brickton, it is well to take note of the principal kinds of clay, and their divisions. The term clay, as ordinarily used, means any earthy substance which, when worked up with water into a plastic mass, will retain whatever shape it is made into. Varying and ever changing proportions of iron oxide, lime and organic matter are found in conjunction with different beds of clay material, and the term, clay, is used to denote them all, including shale. Strictly speaking, however, “clay” means silicate of alumina, or kaolin, said to be derived from two Chinese words (Kau-ling), meaning high ridge, reference being made probably to some location where vast quantities of clay material were found. The greater per cent of silica and alumina (forming kaolin) there is in a clayey substance the more valuable it is, and the nearer it comes to being pure kaolin or true clay. All clays are the result of decomposition, mostly of feldspar, which was a large proportion of the ancient granite rocks, combined with quartz and other minerals, and in the course of decomposition the deposits have been washed and transported for long distances, together with particles of sand and deposited in vast beds, thus forming clay deposits; particularly is this true of fire clay.

At Dayton they have an extensive bed of excellent shale, which is a term also applied to certain clays, not so much because it is composed of different substances or different proportions than other clays, but because it has a thinly laminated structure, the stratification in its formation being well marked. Of this deposit there are none at Ottawa.

There are two classes of clays, viz., high grade and low grade clays. Of the low grade clays they have five of the six subdivisions present upon their properties. 1. Argillaceous shale (present in Dayton only). 2. Silicous clays. 3. Tile Clays. 4. Brick clay. 5. Calcereous clay, and all of the last four at both places. Each kind has its particular adaptability. For instance, the first mentioned is not to be excelled in making paving blocks, the second is adapted to sewer pipes, the third and fourth for roofing and drain tile, and the fifth for common brick. All these varieties exist, and to one accustomed to clay it is not difficult to distinguish the various kinds.

Of the high grade clays, of which there are also six subdivisions, they have two at both places, viz.: 1. Hard fire clay. 2. Plastic fire clay, used for the manufacture of refractory material. These fire clays are a composition of about 59 parts silica, 27 parts alumina, 11 parts water, and 3 parts of iron and other fixing properties. The term, fire clay, is applied without restriction to all clays found immediately underlying coal beds, although the extremely low grade of composition of many of these deposits of so-called fire clays do not warrant their being called fire clays at all. They have the true fire clay, viz., a refractory clay which becomes white upon calcination, i. e., burning the crude clay as it comes direct from the bed.

This fire clay is the material out of which they manufacture their most important products. The upper stratum of common clay and coal is removed and the beds of fire clay exposed, they being from six to ten feet in depth. The clay is then blasted out in large quantities, and conveyed to the dry pan and ground very fine and run over screens, and often shipped in this state to be used as mortar in laying up brick used for refractory purposes. In making brick, after being ground fine it is run through pug mills and then auger machines, and here it comes forth in streams of varying size, depending on the dies used, and cut off by wires into the size and shape desired, except very large or special shapes which have to be hand-moulded or hand-pressed.

They can well be proud of the reputation their brick have attained in Chicago and the Northwest, which is un-paralleled by any of their competitors. They supply material for stack linings, boiler settings, iron cupolas, furnaces, foundries, lime and brick kilns, retorts, and any purpose requiring refractory brick. The beds of plastic fire clay at Brickton, and also to a limited extent at Dayton, have not been touched in recent years, although they are very valuable deposits, as they are adapted for the manufacture of stone ware and articles of that kind.

As to the sidewalk tile and small pavers they cannot be discounted by anyone. They are made from a mixture of the shale at Dayton, or the top clay at Brickton, with a certain per cent of the clay; then the process of manufacture is the same as fire brick, only having a design of some kind pressed on the surface. In order to obtain an even and smooth surface the sidewalk tiles are treated to a salt glaze, which gives them a very pleasing appearance. Miles of their sidewalk tile can attest their usefulness, in Ottawa alone, to say nothing of the great quantities recently shipped to cities and villages in this state where the idea of using tile for sidewalk has just taken effectual hold upon the people. They are cheaper and more lasting than cement walks, less expensive than stone, better in appearance, more desirable than wood, and when properly laid make the most durable walks that can be had. Although the atmosphere and its destructive agencies decomposed the massive rocks from which comes the clay used to make these tile, yet if it is properly vitrified and placed where it will not be broken or destroyed by abrasion, it will be a tablet that will last forever, absolutely indestructible by the atmospheric agencies or the elements. Making articles from clay was the first manufacturing industry in the world, and it is to-day the second largest industry in the United States; and it can be said that as long as the earth lasts, brick will be made, and the future inhabitants will be able, 4,000 years hence, to find remains and specimens of the products of this age, as we today can and do look upon authentic specimens of brick made over 4,000 years ago.

from the Ottawa Republican-Times, date unknown