OLD DAYTON

Some Reminiscences of the Ancient Village on the Banks of the Fox River

A representative of The Free Trader visited the village of Dayton last Tuesday, drawn thither by the report that considerable damage had been done in that place by the remarkable rise of the Fox river during the recent freshet. Very few of the readers of this paper are not acquainted with the history of the early days of this historic village, which had it not been for the legislative blunder of William Stadden, state senator from this district during the canal agitation, the place, instead of containing 300 inhabitants, as it does today, might be a manufacturing city with a population as large as that of this city.

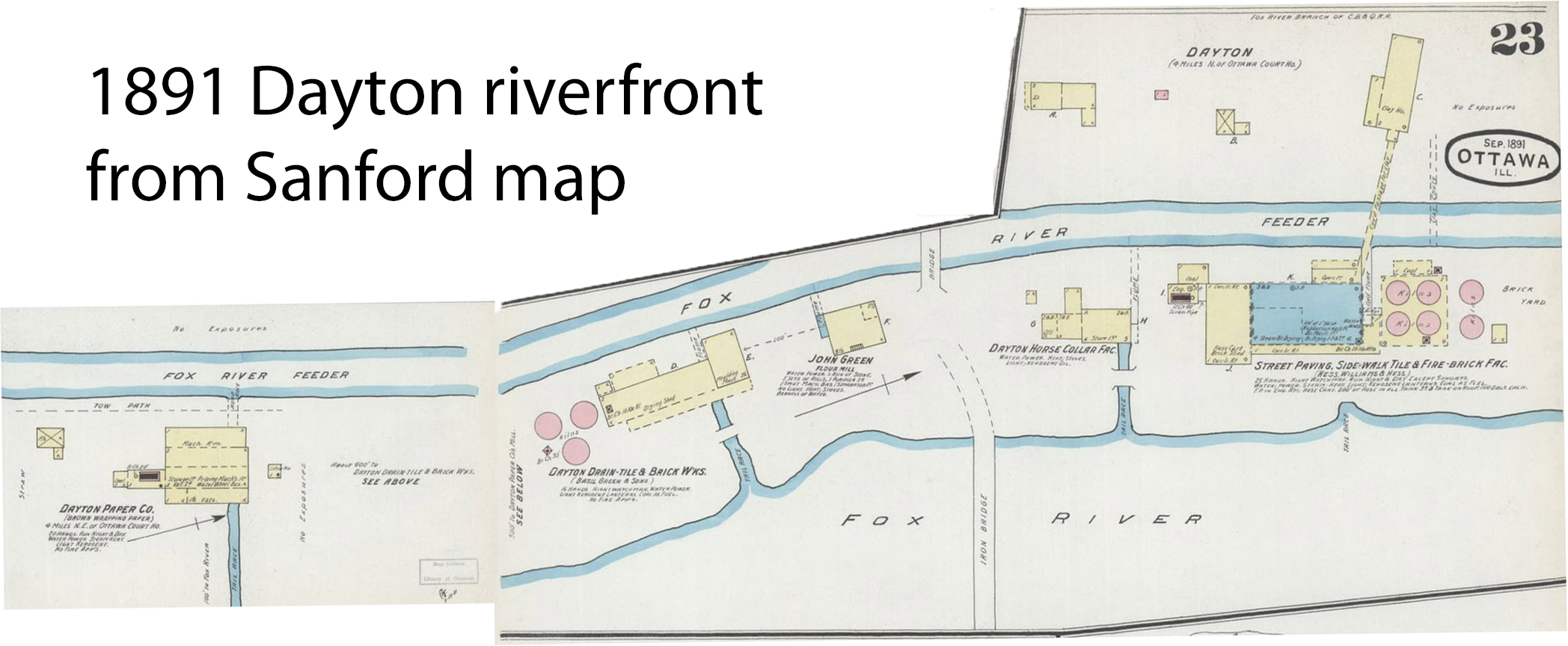

It was principally through Stadden’s advocacy that the canal terminus was made at La Salle, instead of Ottawa. He was a nephew of John Green, the founder of Dayton, and believed that by having the canal terminate at La Salle he was working for the interests of himself and Dayton. It was his intention to have a navigable feeder from Dayton to Ottawa, which would afford abundant water power for manufactories. Had the canal terminated at Ottawa there would, of course, be no necessity for a feeder. Had the canal ended at the latter city, as it probably should have done, there would be no La Salle or Peru today, and Ottawa would be a city of 50,000 inhabitants and Dayton a large manufacturing point. Lots that sold in that village in 1836 for $500 can now be purchased for $5. In canal days Dayton was a larger place than Ottawa. The cost of running the canal to La Salle would have improved the river to this point, making it navigable for Mississippi river steam boats; and the Illinois Central Railroad would have [illegible] here. But Stadden and those he won over to advocate his views willed all those things otherwise through a huge-sized mistake, which was practically the death-knell of Dayton.

Jesse Green, who is the oldest settler in La Salle county, came to the place with his father in the winter of 1829, from Newark, O. They brought with them mill wrights and mill-irons, and the following July had a grist and saw mill in operation, the mill stones being made form two large boulders. On the east side of the Fox river was then a lodge of the friendly Pottawattomies. At the time of the Blackhawk was, in 1832, John Green was obliged to erect a palisade fort around his dwelling. It was at this time the massacre occurred on Indian Creek by the Sacs and Foxes, in which 15 white people were tomahawked and scalped. During this period the supplies for the Green family were obtained at the store of Geo. E. Walker, located where now are the mineral springs.

At the close of the first year of its settlement Dayton had but 21 inhabitants. Resin Debolt, Henry Brumbach, uncle of the deceased county surveyor George Brumbach, and Daniel Grove, father of Samuel Grove of Utica township, had moved into the vicinity, making in all but three neighbors of the infant colony. In those days there were plenty of wild animals in this region, such as deer and wolves, but only one bear was ever seen hereabouts by the old settlers.

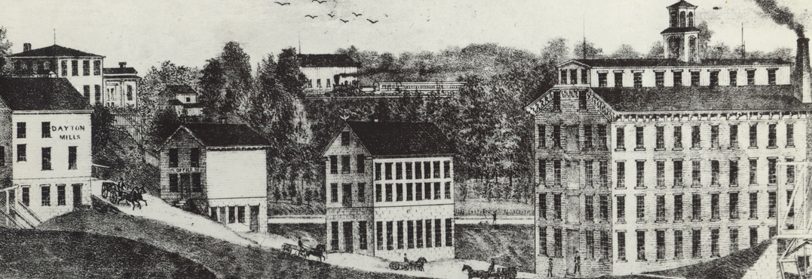

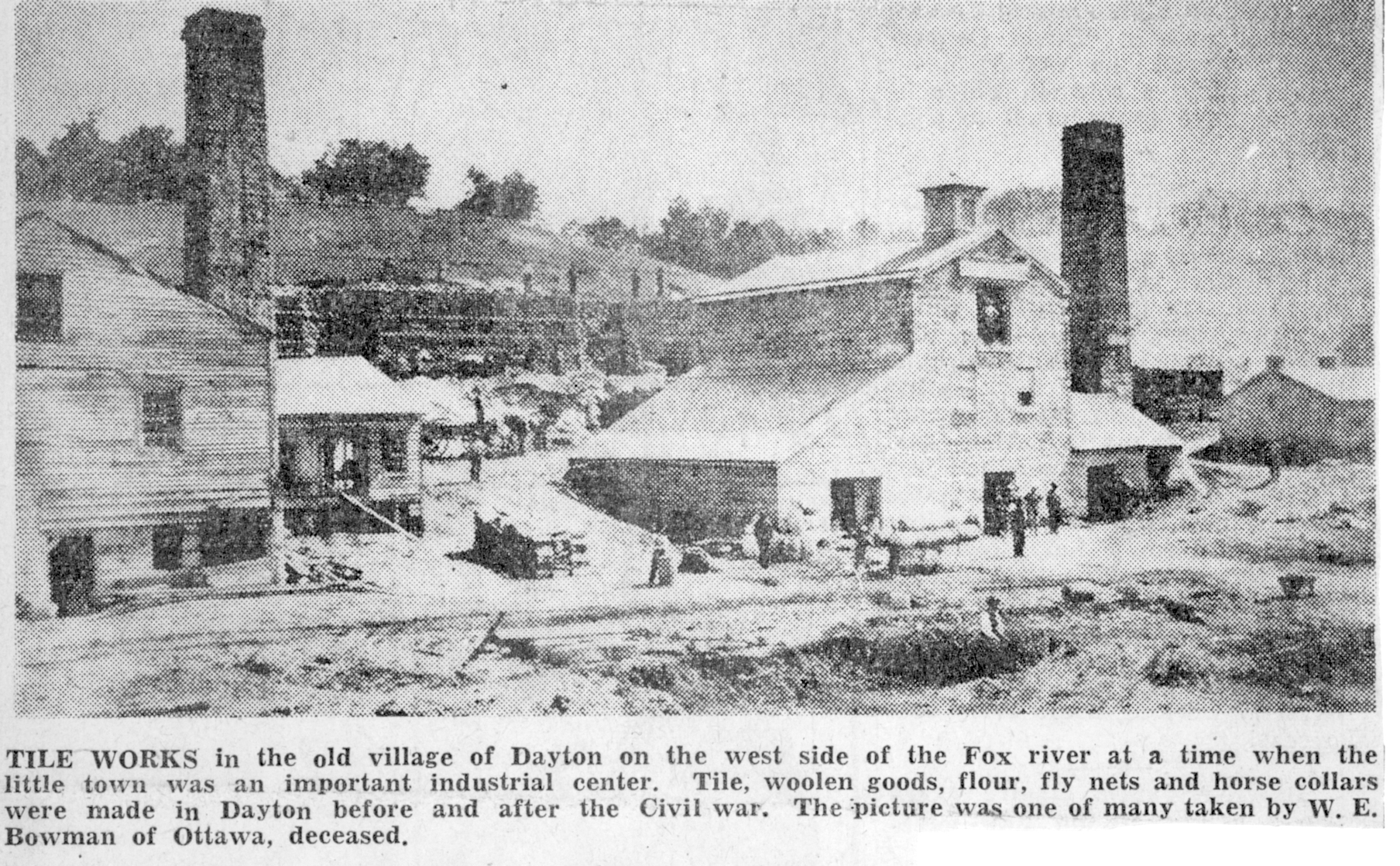

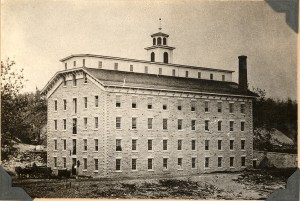

The fame of Green’s Mills from 1834 to 1875 was extensive throughout this region. In the early years of Dayton’s history teams traveled 100 miles to these mills. In the last ten years the flour business has greatly fallen off. John and Charley Green, the proprietors, also run a tile factory. The woolen mills were run by the Greens since 1842. A few years ago they were closed and a pressed brick factory started in the large stone building. The fitting up for this business cost $15,000. The pressed brick factory is in the hands of a stock company; capital, $50,000. One machine has already been put in which weighs 17 tons and cost $3,500, having a capacity of 25,000 brick per day. More machines will be put in during the season, making the total capacity 100,000 per day and giving employment to 50 men. The flood of Jan. 6 has delayed the starting of these works, which would have been in operation this week but for this occurrence. Considerable damage was done to the works by the freshet.

The old woolen mill was erected by J. & D. Green in ’40, and two years later manufacturing commenced. This mill had the first power loom of any in the state. The Greens did a thriving business until 1864 when they erected a new woolen mill — the building which is now the pressed brick factory. The erection of the mill far exceeded their expectations, costing them $65,000.

The next year they bought 60,000 pounds of wool, averaging a cost of $1 per pound. The next season wool dropped from 45 to 50 cents per pound and the firm lost between $30,000 and $40,000, and later on the firm met with another heavy disaster by the burning of $22,000 worth of wool stored in Chicago, and which went up in the great fire. The result of these heavy losses was that the firm was obliged to close its doors, and the woolen industry then was over.

The paper mill owned by H. B. Williams is closed for the winter, having at this time a large surplus stock on hand. It gives employment to 15 men.

The Horse-collar factory was established in 1865. In ’70 A. F. Dunavan & Son purchased the business, which employs about ten hands. It has a capacity of 12 dozen collars per day, manufacturing 25 different grades, ranging in price from $6 to $25 per dozen. The firm has, piled up in its storerooms, $8,000 worth of horse-collars awaiting shipment. The demand is principally in the spring months, and the collars manufactured here are sold throughout this and adjoining states, and in New York, Pennsylvania, Virginia, and California. The firm buys for cash, getting inside prices on material, and by struct and honest dealings the firm sends its goods over a wide area of territory, competing in price and quality with any factory in the United States. This the Dunavans are enabled to do, as they make collars a specialty. In the summer season leather fly-nets are manufactured here. The junior member and another agent are on the road in the interest of the business. The firm have $15,000 invested in their manufactory. A. F. Dunavan, a very courteous and obliging person to met, kindly showed the Free Trader man through the building, where every person was busy as a nailer in the manufacture of that portion of the collar entrusted to him. This factory was also damaged by the high water, which flooded the basement, tearing up portions of the floor.

Dayton has a neat, two-story public school, presided over by Ottawa ladies — Miss Jennie Crane in the higher department, with Miss Mary Miller in the primary. About 70 pupils are in attendance.

A Sabbath school of 75 members is one of the worganizations of the viallage. The superintendent, Basil Green, being absent, his place is supplied by Jas. A. Green.

Itis the proud boast of the little village that it never had a saloon within its borders.

Chas. Miller, Jesse Green, O. W. Trumbo and Geo. W. Makinson are the only names on the roster of postmasters of this place. The latter is probably the oldest postmaster in this state, having been appointed by President Buchanan in ’54. Thirty years of continuous service as postmaster at Dayton will, unquestionably, give him a reappointment under the new administration. The office is a little structure — 2×4 feet, in the only store the village possesses.

Jas. Timmons runs the Dayton Hotel and has a monopoly of that business, and he fears no rival.

In the first few months of its existence Dayton had more inhabitants than the Chicago of those past days. Yet it is pleasantly and very romantically situated, and will always from its traditional and historic associations be an object of much curiosity and interest to the tourist. In the summer weather it is a popular fishing resort and the stamping ground of many a picnic party.

Tuesday night, Jan 6, the Fox river at Dayton reached its highest point in the memory of the oldest inhabitants. Within 50 years, with one notable exception — the rise of ’59 — the river had not reached such a height. In a few hours, by the gorging of the ice at Howland’s Rapids, about a mile from its mouth, the river at Dayton rose 30 feet about high water mark, reaching to the second floor of the old woolen mills. The chimney of the pressed brick works was demolished and a large lot of lumber swept away. The river banks on both sides were strewn with ice, thousands of tons being piled up by the flood. Tuesday last there were fears entertained of another freshet, as the ice was beginning to gorge as it had done the night of the 6th.

One of the oldest roads laid out by the state was the one which crossed the Fox river at Dayton. Ten years ago the bridge was carried away by the ice, and since that time no means has been provided to cross the river at that point. The county agreed some time ago to pay half the expense, leaving to the township of Dayton and Rutland one-fourth of the cost each. It is not at all probable that this bridge will be rebuilt for some years, unless the townships named take a more active interest in the agitation of the project.

The representative of the Free Trader is indebted to Mr. and Mrs. Jesse Green for courtesies while in the village, for which he thanks them kindly. Mr. Green’s father, the original settler of the place, once owned 1,000 acres of land in that vicinity.1

- The Ottawa Free Trader, January 17, 1885, p. 5.