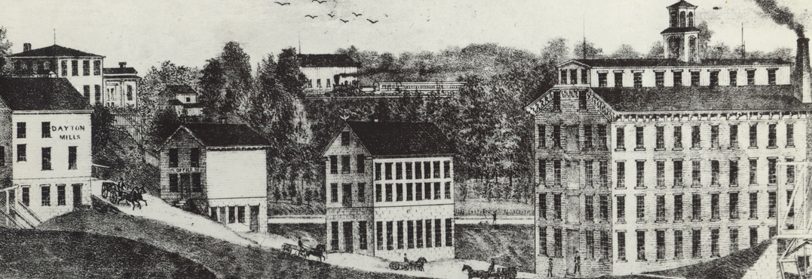

The Dayton Woolen Mills

La Salle County, and Dayton especially may refer with just pride to the factory of J. Green & Co., as turning out a quality of woolen goods, cassimeres, doeskins, flannels, etc., that is not excelled anywhere in the west. Although this firm has made no attempt to push the goods upon the market by puffing in the newspapers, depending entirely on the quality of the articles to effect sales, yet the Dayton goods are widely known, and the dry goods merchant need only, as many of them do, offer the article with the single remark, “Dayton goods,” to call the attention of the purchaser to the beautiful texture and finish of the cloths manufactured in this establishment.

The rapid strides made in the west, within the past ten years, is producing a superior article of woolen goods, is admitted even by the older establishments of the East, and no man, at this day, need look for any finer article than is made at home, as he surely cannot find a better. To show the public appreciation of the Dayton goods, it need only be dais that the agent of the firm recently took orders in the city of Davenport, in one day, for goods to the amount of $1500, and the sale is all the more important when it is considered that that city has mills of its own.

The present factory building is of stone, built in the most substantial manner, situated on the right bank of the Fox river just above the bridge. Its dimensions are 50 by 100 feet in the clear, and four stories high, besides the attic. It was built in 1864, when the old mill was found to be too small for the increase of the business. Entering on the lower floor, the wool is seen on the left hand, the dressing machines on the right, and the fulling and carding apparatus at the opposite end, while an addition beyond contains the steam works used in heating the building and furnishing the necessary hot water used in the various processes of manufacture.

The machinery is driven by a turbine wheel placed under this floor, and propelled by the water from the feeder that flows past the mill/ The floors above are used for carding, weaving and spinning, there being two sets of carding machines of three in each set, making nine in all, besides a machine that turns out the rolls that feed the housewife’s spinning wheel. The third floor contains fourteen looms in all, eleven of them for double fold, and three making cloth of treble width; these wide machines being a great saving over the loom making cloth, but one yard wide, since both require the same attendance. These looms, when in full blast, make a music peculiarly their own, the nail machine being the only contrivance that beats it in racket.

Of spinning machines there are six, four of them having 2540, and two running 216, spindles each, making an aggregate of 1,392 spindles, tended by six men. Just think how many women it would take with the old family concern to twist all this yarn, that is done so easily by these six men. And these machines can be set so as to make yarn coarse or fine, nor can they fail in spinning it absolutely even throughout. About fifty hands are employed, a dozen of them being females, the rest men and boys.

The factory will consume this year about 120,000 lbs of wool. The carding machine is supplied with teasels, imported from the State of New York, which seems to be unnecessary, as they might be produced here, and the transportation saved to the company or put into the pockets of our farmers. Why has this not been done?

The sales of the firm show that manufacturing efforts in the West are appreciated. Still the mill is not run up to its full capacity.1

- Ottawa Republican, Thursday, August 18, 1870, p. 2.